PRODUCTION ADVANTAGE

Printing workshop

The company has a dust-free workshop and a full set of environmental protection treatment equipment, equipped with a full-automatic screen printing machine. It has developed and designed a production process of multi machine assembly line printing, that is, a multi-color printed sheet is linked to multiple printers through a full-automatic drying assembly line.The whole printing process can complete the overall printing of the sheet, which greatly improves the work efficiency without replacing the screen and airing.

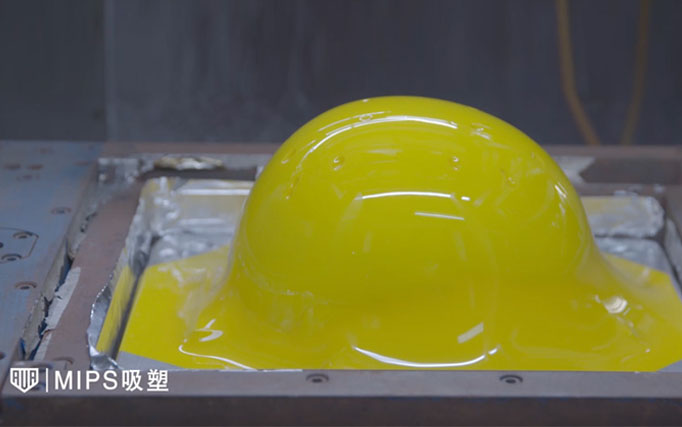

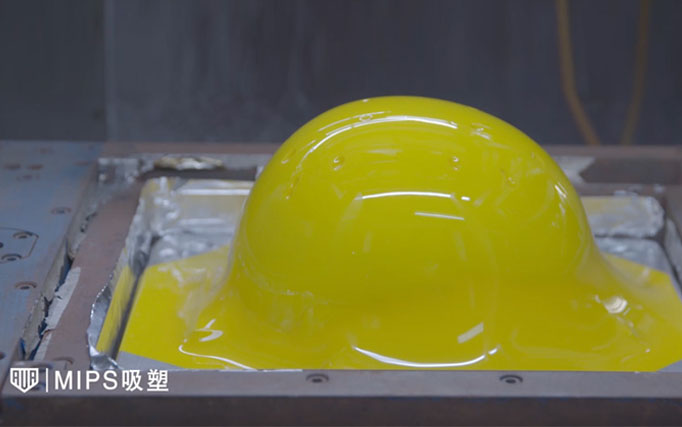

Blister workshop

The company's Vacuum Forming workshop has 1 out 2, 1 out 4, 1 out 6 and other types of vaccum forming machines. The innovative introduction of 4-axis robot loading and unloading method has greatly saved labor and improved production efficiency. The workshop has an independent waste heat collection system, which is supplemented to the drying room to greatly save energy consumption.

Cutting workshop

The company's trimming workshop is equipped with semi-automatic punching lines, full-automatic 5-axis cutting machine tools, and ABB and Mitsubishi full-automatic 6-axis robot cutting equipment. In the mass production of products, semi-automatic punching lines and 5-axis cutting machine tools with higher fluency of man-machine cooperation are used. The programmable 6-axis robot flexible trimming method is used for small batch pilot run and proofing, which greatly shortens the time for pilot run and proofing.

Painting workshop

The painting workshop of the company is equipped with a full set of environmental protection treatment equipment to realize zero discharge of waste water and waste gas. The workshop has a manual semi-automatic spraying line, and the newly introduced automatic electrostatic coating line increases the processing speed of painting.

Water mark production workshop

The company's water decal printing workshop has a dust-free workshop and is equipped with a full-automatic water decal printing machine. The design and production of water decal are completed independently in the factory.

Injection workshop

The injection molding workshop of the company has various types of injection molding machines. All injection molding machines adopt the truss robot or 6-axis robot supporting conveyor line blanking mode. The introduction of dynamic mold equipment greatly reduces the mold changing time.

Composite material comprehensive workshop

The company has a comprehensive workshop for composite material processing, Which is capable of producing shells and helmet accessories made of glass fiber reinforced plastics, carbon fiber, Kevlar, etc. It adopts the airbag internal support curing molding process, and uses the advanced Korean dual position water jet cutting technology and Sweden ABB 6-axis robot fully automatic grinding technology, which greatly improves the production capacity and quality.

EPS molding workshop

The company's EPS molding workshop is equipped with various types of EPP/ EPS molding machines and imported foaming machines. The use of the fully imported foaming machine can control the foaming stability of EPS, the main material of the product, at a higher standard, and the innovative use of the mold shifting molding process has greatly reduced the molding time of the helmet body with built-in accessories.

Mold design and processing center

The mold processing center of the company is equipped with various types of precision carving, high-speed milling and other equipment, and all molds required for production are produced and manufactured internally. The center has 3D scanning, 3D printer and many other equipment, which can realize the synchronous development of EPS molding mold and vacuum forming mold, greatly improving the matching rate of shells and EPS/EPP .